The Circle Series offers improved performance compared to traditional machines available on the market. It has 2 times the sorting accuracy, 3 times the processing capacity, requires only 1/5 of the floor space, and consumes 1/3 of the energy. In addition, it can be monitored remotely at all times.

The Circle Series ore sorting machine features an ultra-small footprint, saving up to 75% of floor space compared to traditional belt conveyor-type sorting machines. This significantly reduces installation and infrastructure costs for existing processing plants.

HPY offers flexible configurations with single-energy or dual-energy X-ray sensors, precisely tailored to ore properties.

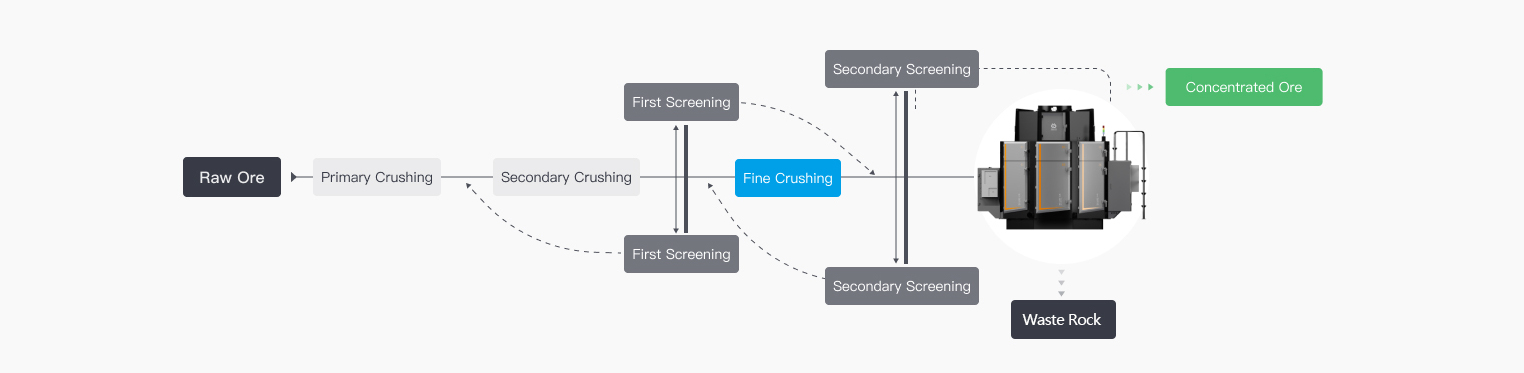

These combined advantages enable effortless retrofitting into any existing beneficiation process.

The processing capacity of the machine is 330% higher than previous generations of ore sorting machines. With a particle size range of +10-60mm, the processing capacity can reach 150 t/h. A single machine can meet the requirements of a mineral processing plant with a production capacity of 3000 t/d.

| Model | HPY-CM1700 | HPY-CN1700 | HPY-CC1700 |

|---|---|---|---|

| Ore Type | Metallic Ores | Non-metallic Ores | Coal |

| Particle Size (mm) | +10-60 | +10-60 | +10-60 |

| Power (kW) Excluding Air Compressor | 22 kW | 22 kW | 22 kW |

| Dimensions (LxWxH mm) | 5100*3273*4070 (Height with Discharge Bin: 5450mm) | 5100*3273*4070 (Height with Discharge Bin: 5450mm) | 5100*3273*4070 (Height with Discharge Bin: 5450mm) |

The world’s first ring-shaped ore sorting machine boosts a super-large processing capacity and a wide processing particle size range.

Utilizing aerial imaging technology, the machine's imaging quality has improved by 30%, and its AI computing ability is increased by 400%. It is capable of processing over 10,000 ores per second.

The separation system uses high-speed multi-row air jets with a single nozzle diameter of 2mm. The multi-jet system allows for high accuracy, starting at 5mm.

The machine also features intelligent automatic control, allowing for online monitoring.

- Exceptional Throughput & Versatile Sizing.

- Superior Recognition Accuracy.

- High-Precision Separation.

- Compact, User-Friendly Design and Maintenance.

- Highly Adaptable & Customizable.

Circle Series 3D | The Ultimate Guide to HPY's Large Processing Ore Sorting Solution

Everything you need to know about HPY's Circle Series ore sorter:

✅Processing capacity

✅Particle size range

✅Power

✅Potential applications

Achieve the Largest Mineral Processing Capacity: The World’s First Ring-Shaped Ore Sorter Upgrades

Step inside HPY's manufacturing facility to discover the latest upgrades to our Circle Series, designed for efficient sensor-based #oresorting. With a unique ring-shaped design, the Circle Series maximizes processing capacity without the need for larger belts, replacing 2-3 traditional belt sorters.

Circle Series and Dry Coal Sorting

Did you know the Circle Series ore sorting machine could also be used for dry coal sorting?