Project

By using HPY Technology’s sensor-based ore sorting machines for pre-concentration, waste rock is removed during the crushing stages and the company can now mine below cutoff grade areas. Ore sorting can enrich the low-grade ore and remove the excess waste rock for higher resource utilization. Yunnan Tin and HPY Technology have agreed to continue collaborating on ways to incorporate ore sorting to enhance the tin industrial chain and reuse tin-copper waste rock stockpiled to recover valuable minerals.

Economic Benefits

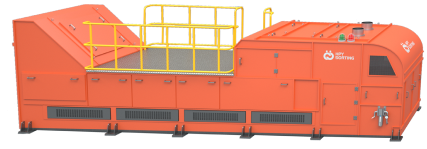

According to data given from the Datun Tin Mine, which uses one Classic Series

- 100,000 tons of pre-rejected waste rock per year

- 1.4 million USD per year in reduced mineral processing costs

- 214,000 USD per year in reduced tailings disposal costs

- 370,000 USD per year in reduced tailings pond expansion costs

Yunnan Tin Group - Laochang Mineral Processing Plant

Raw Ore Grade: Sn 0.328% Cu 0.42%

Waste Rock Grade: Sn 0.013% Cu 0.060%

Concentrate Grade: Sn 0.489% Cu 0.613%

Particle Size: +10-60mm

Rejection Rate: 35.2%

Yunnan Tin Group - Laochang Tin and Copper Mine

Raw Ore Grade: Sn 0.456% Cu 0.26%

Waste Rock Grade: Sn 0.016% Cu 0.077%

Concentrate Grade: Sn 0.679% Cu 0.368%

Particle Size: +10-60mm

Rejection Rate: 36.8%