Guizhou, a province situated in the Southwest area of China, is well known for its mountainous terrain. The downside to this is its limited transportation options before modern China began its massive infrastructure projects, making it extremely difficult to travel to and from the region. However, these mountains also held valuable resources, particularly coal.

Back in 1885, Guizhou Governor Pan Wei reported to the Qing court: "Guizhou is barren and poor; all areas are mountainous, although it is rich in mineral resources, especially coal and iron." Using data from 1996, Guizhou's coal-rich areas accounted for over 40% of the province's total land area. Of the 86 counties, 74 produced coals. Back then, only 10% of the coal resources were being excavated and utilized.

To unlock the full economic potential of Guizhou's coal mines, many, including Guizhou Guineng Investment Stock Co., have resorted to giving their mines a 'technical' upgrade. In 2020, Guineng's deputy general manager, Hongdeng Qiu, stated, "Beginning this year, we will vigorously promote the innovation and application of artificial intelligent equipment and technology, especially integrating the Internet, big data, and coal mining technology."

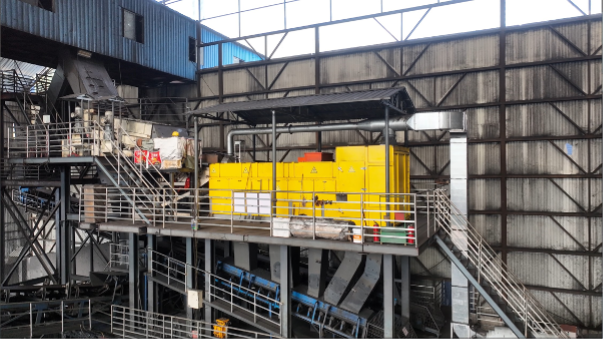

With the aim of revolutionizing the coal beneficiation process, increasing coal production, and reducing environmental pollution, Guineng decided to collaborate with HPY Technology and utilize their Golden Coal Series dry coal sorter in their Hebian Coal Mine, located in the city of Liupanshui, Shuicheng county. In 2020, the mine's annual coal production capacity was only 300,000 tons. According to the mine's electromechanical deputy manager, the mine has grown to 600,000 tons per year.

Before adopting HPY's dry coal sorting machine, Hebian mine used a large amount of water and various chemicals for coal sorting. This has been known as the “wet” coal preparation method, also the most prevalent process sorting coal and gangue in the industry. Not only flotation and dense medium cyclone need to be built under this method. It also meant that the mine needs to build a special treatment facility to deal with the wastewater afterward, incurring additional expenses and higher demands for process water. With HPY's dry coal sorting method, it occupies significantly less space, is easy to assemble and operate, and conserves water resources.

The mine opted for a 1.6-meter-wide Golden Coal Series dry coal sorter, directly connected to the wellheads to pre-reject the gangue using the machine. HPY Technology's Golden Coal Series can process coal using a specially designed X-Ray sensors, recognizing the carbon inside the coal and separate it from the waste rock. The Golden Coal Series in particular, could sort coal at a speed of 180t/h, reducing the gangue content to less than 1%, rejecting more than 95% of the gangue, and increasing the calorific value from 2000 to 4000 Kcal. By eliminating the waste rock in coal, HPY's Golden Coal Series eliminates a significant transportation cost.

A simple calculation of the numbers highlights the economic advantages of the Golden Coal Series:

Hebian Coal Mine Production Capacity: 600,000 tons

40% of raw ore's particle size: +40mm

The ratio of raw ore to gangue entering the system is approximately 50%

Golden Coal Series Annual Gangue Rejection: 600,000 * 40% * 50% = 120,000 tons per year

Savings on the cost of coal flotation: 20 CNY/ton * 120,000 tons = 2,400,000 CNY/year

Savings on the cost of transportation: 30 CNY/ton * 120,000 tons = 3,600,000 CNY/year

Low cost of operating the machine: 1.5 CNY/ton * 600,000 tons of raw ore * 40% (ratio of raw ore entering the sorting system) = 360,000 CNY/year

Total: 2,400,000 + 3,600,000 - 360,000 = 5,640,000 CNY/year

In Hebian Coal Mine, HPY Technology helps save transportation and flotation costs to the tune of $770,000 USD per year. Currently, the company is still conducting tests on the 2nd generation of the Golden Coal Series. However, statements from the development leader reveal that the new generation has made a breakthrough in their sorting air jets, reducing maintenance time and making it the most long-lasting in the current industry.